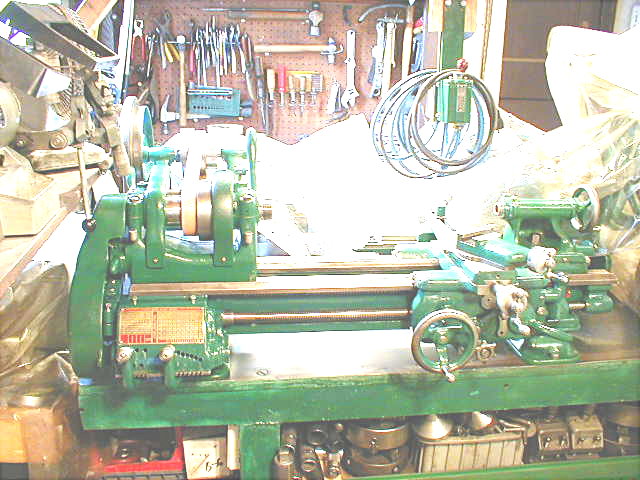

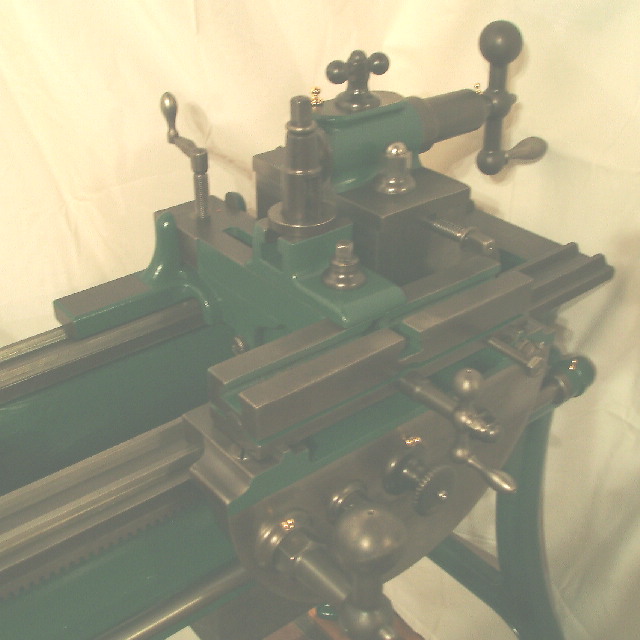

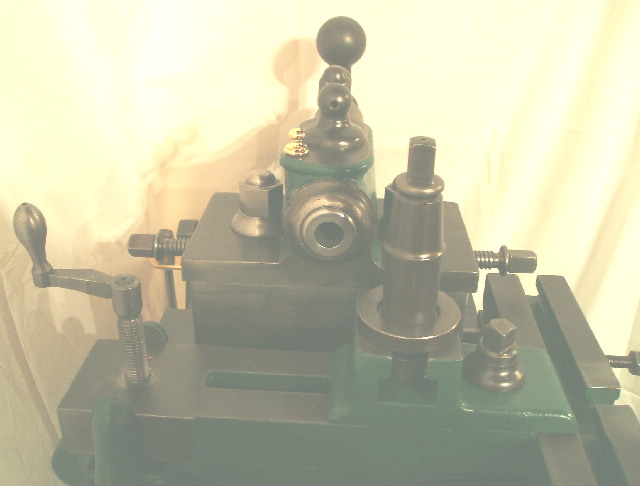

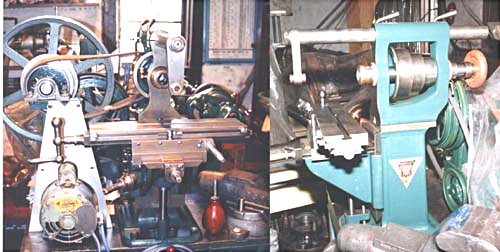

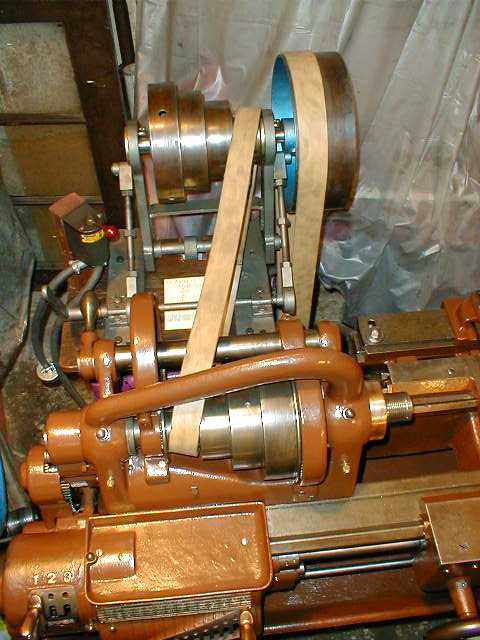

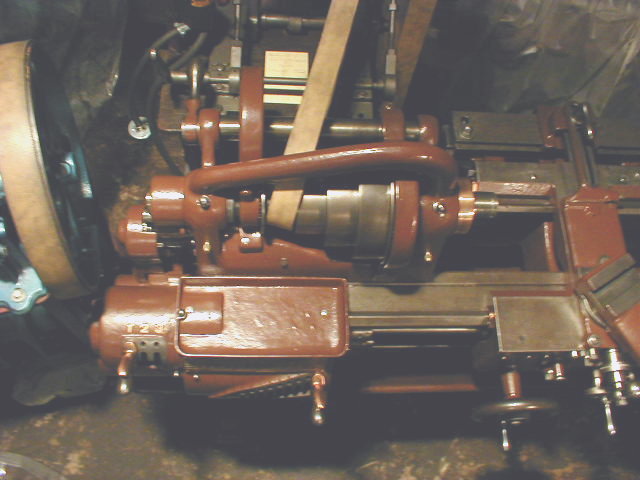

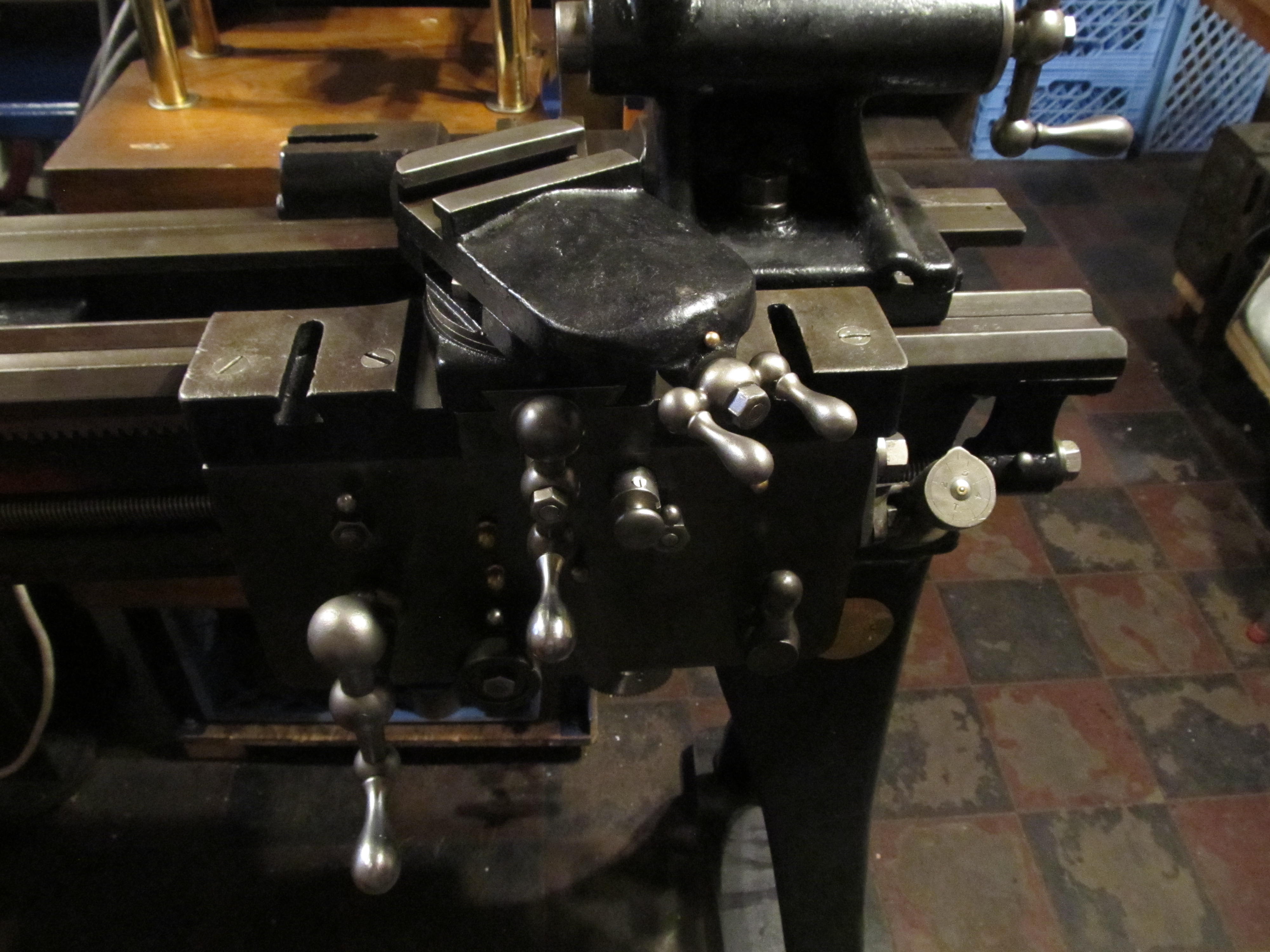

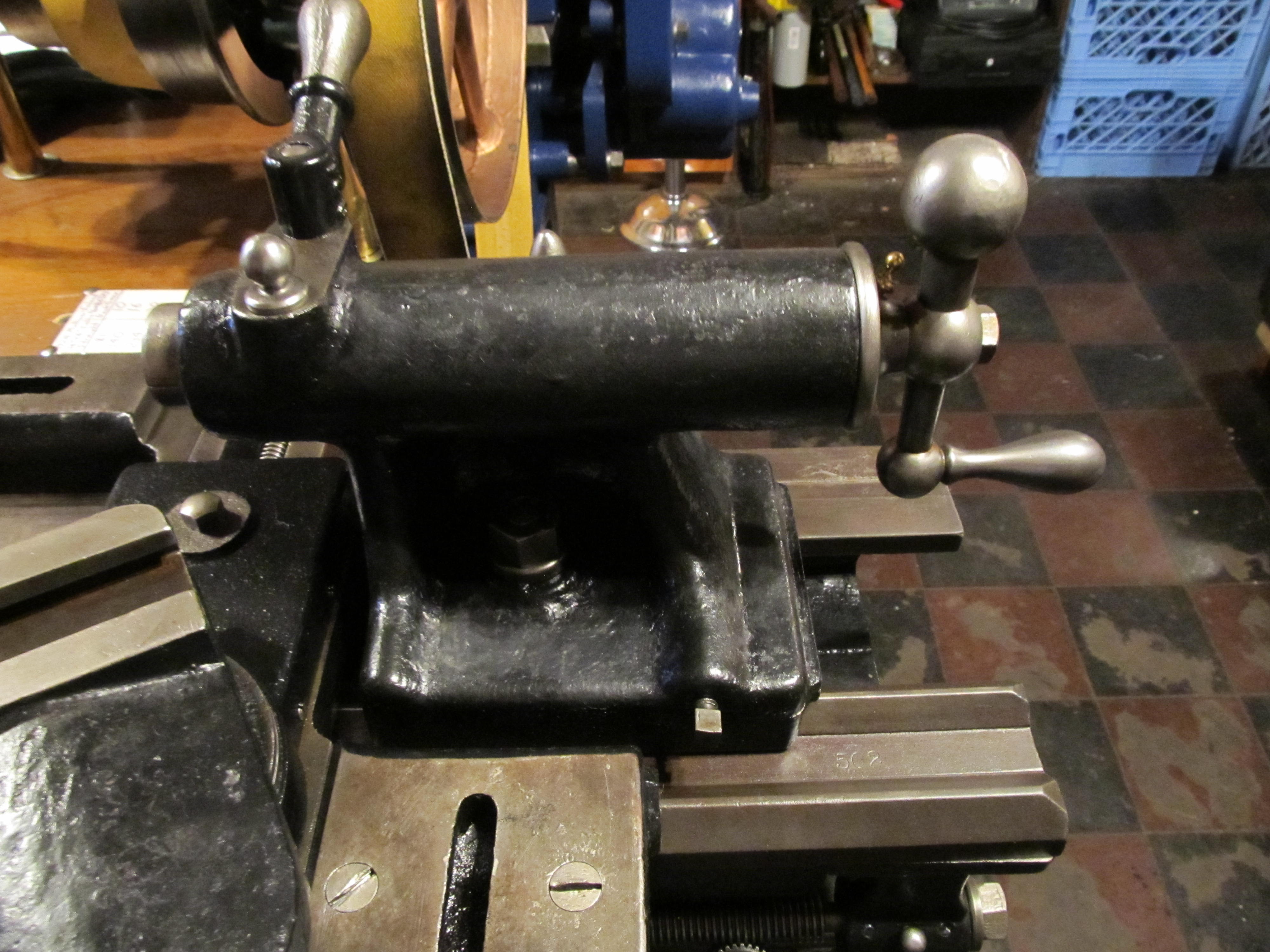

South Bend Lathe 9″x3′ 1938: This lathe is pre war but was used in a mobile shop unit for WW II. It will shortly be undergoing an upgrade from a Model C to a Toolroom Model with the addition of : cross slide clutch apron, taper attachment, quick change gear box and direct reading dials on compound and cross slide (which was drilled and tapped for the milling attachment) and 12 spindle speeds. South Bend Lathe 9″x3.5′ 1937: This unit saw much wear and tear. All new taper attachment, upgrade to Toolroom Model specs., spindle buildup-head stock line bore and 12 speed conversion. We can custom build-spec. 9″ units to order. Parts inventory on hand for these.

South Bend Lathe 9″x3.5′ 1937: This unit saw much wear and tear. All new taper attachment, upgrade to Toolroom Model specs., spindle buildup-head stock line bore and 12 speed conversion. We can custom build-spec. 9″ units to order. Parts inventory on hand for these. South Bend Lathe 11″x5′ 1924: A 5′ bed makes this unit ideal for medium shafting work. It came in with no bed wear and in good shape, but many end and apron gear teeth had to be replaced.

South Bend Lathe 11″x5′ 1924: A 5′ bed makes this unit ideal for medium shafting work. It came in with no bed wear and in good shape, but many end and apron gear teeth had to be replaced. Putnam Lathe 14″ x 4 1/2′ 1860 – 1865: This machine is extrodinarily old and complete. It is currently undergoing a full restoration. The age reflects the fact that the Precision Machine Tool Museum at Winsor, VT. has a near identical unit dated 1854. As well, we have found a catalogue page dated 3-1-1865 from New York Steam Engine Co (the machine pictured had some later features). The tail stock is stamped with this makers name. It appears that there was some collaberation between these makers. Castings or the whole lathe could have been made for N.Y.S.E. Co. buy Putnam. Our machine is stamped Worcester, Mass. (where N.Y.S. E. Co. had a factory before 1869) and 222 Pearl St. N.Y. (where N.Y.S. E. Co. had a wharehouse and showroom). N.Y. S. E. Co. were distributors of “patent chucks at manufactures prices” and perhaps machine tools. Gavin and Manning, Maxwell & Moore had a similar structure. Our lathe has no lead screw or back gears as built. It is a “plain lathe” in that it only has a feed rod. There is no steel on this lathe save a thrust cup washer for the headstock spindle an feed reverse lever handle (both thin sheet stock). The lathe is of all wrought iron and cast iron in it’s main parts. The gears are cast, not machined. All tool marks are from a planer or lathe. There is much hand fitting with filing and polishing. This machine predates mass production techniques and standard fasteners. The fasteners are either hand wrought and die threaded or machined on a lathe. As an example he headstock bolts are turned between centers and spec. out at 7/16″ x 13 TPI (!).

Putnam Lathe 14″ x 4 1/2′ 1860 – 1865: This machine is extrodinarily old and complete. It is currently undergoing a full restoration. The age reflects the fact that the Precision Machine Tool Museum at Winsor, VT. has a near identical unit dated 1854. As well, we have found a catalogue page dated 3-1-1865 from New York Steam Engine Co (the machine pictured had some later features). The tail stock is stamped with this makers name. It appears that there was some collaberation between these makers. Castings or the whole lathe could have been made for N.Y.S.E. Co. buy Putnam. Our machine is stamped Worcester, Mass. (where N.Y.S. E. Co. had a factory before 1869) and 222 Pearl St. N.Y. (where N.Y.S. E. Co. had a wharehouse and showroom). N.Y. S. E. Co. were distributors of “patent chucks at manufactures prices” and perhaps machine tools. Gavin and Manning, Maxwell & Moore had a similar structure. Our lathe has no lead screw or back gears as built. It is a “plain lathe” in that it only has a feed rod. There is no steel on this lathe save a thrust cup washer for the headstock spindle an feed reverse lever handle (both thin sheet stock). The lathe is of all wrought iron and cast iron in it’s main parts. The gears are cast, not machined. All tool marks are from a planer or lathe. There is much hand fitting with filing and polishing. This machine predates mass production techniques and standard fasteners. The fasteners are either hand wrought and die threaded or machined on a lathe. As an example he headstock bolts are turned between centers and spec. out at 7/16″ x 13 TPI (!).

South Bend Lathe 13″x5″ 1929: A well worn unit that needed head stock bearings, tail stock quill, apron clutch rebushing, gear tooth repair, compound crack repair and gear box work. Since this picture, the lathe is now driven by a wall mounted counter shaft assembly.

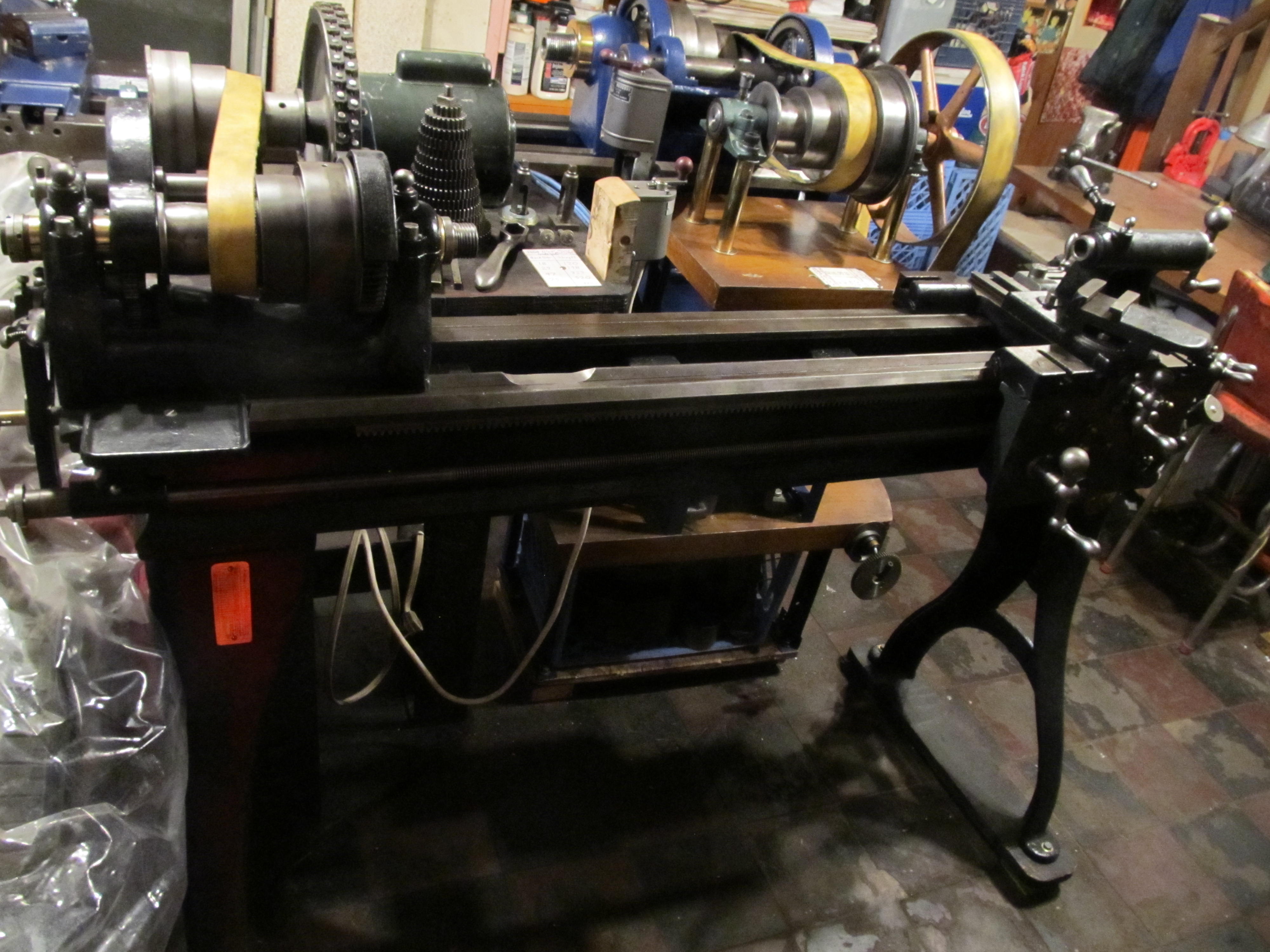

South Bend Lathe 13″x5″ 1929: A well worn unit that needed head stock bearings, tail stock quill, apron clutch rebushing, gear tooth repair, compound crack repair and gear box work. Since this picture, the lathe is now driven by a wall mounted counter shaft assembly. South Bend Lathe 15″x5′ 1913: Coming in to us in great condition, resto was simpler on this lathe. It has served as a benchmark example for the other early South Bend lathes. This works as a new time capsule lathe!

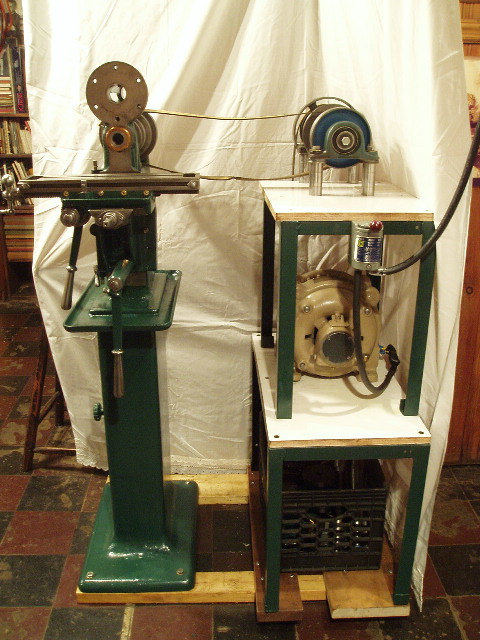

South Bend Lathe 15″x5′ 1913: Coming in to us in great condition, resto was simpler on this lathe. It has served as a benchmark example for the other early South Bend lathes. This works as a new time capsule lathe! S.W.Putnam Sons Drill 16″ 1885: Two views here: right an left of this machine. The drill was in daily use until 1985!!! There was abuse and neglect very evident here, but the integrity was still intact. Very little data is available on this unit (thanks to Frank Morrison for help) and restoration and research is on going. Since photographed, it has countershaft drive and under power.

S.W.Putnam Sons Drill 16″ 1885: Two views here: right an left of this machine. The drill was in daily use until 1985!!! There was abuse and neglect very evident here, but the integrity was still intact. Very little data is available on this unit (thanks to Frank Morrison for help) and restoration and research is on going. Since photographed, it has countershaft drive and under power. South Bend Lathe 18″x6″ 1911: A very early South Bend Lathe. Totally worn out, stored outside, badly repaired and horrible driveall attached. What haven’t we done to this one! This lathe recently machined an 18″ O.D.x 9″ I.D.x 6.75″ long cast iron main bearing ring for a 4′ elliptical chuck we engineered in the studio. How’s that for a come back!!!

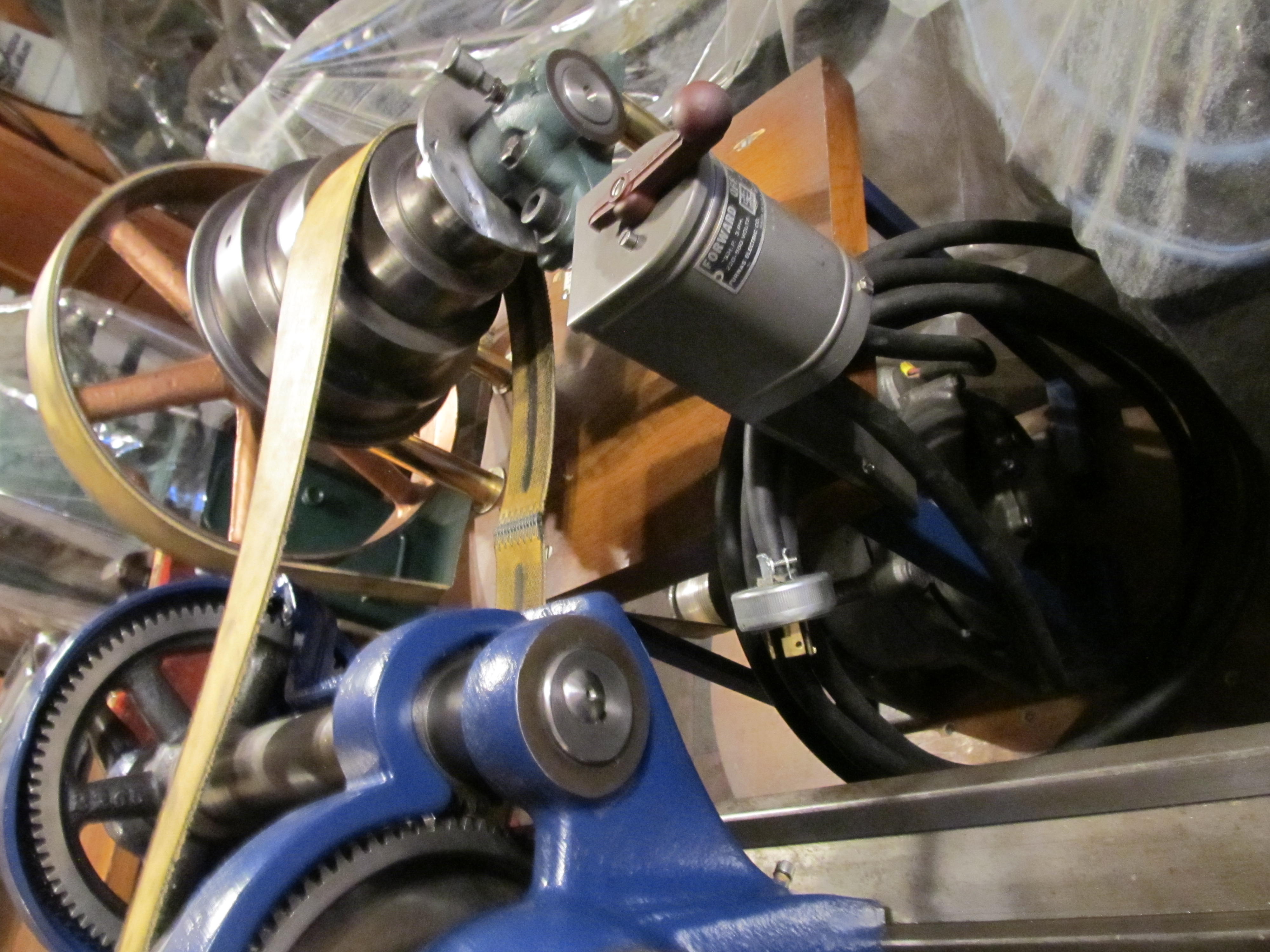

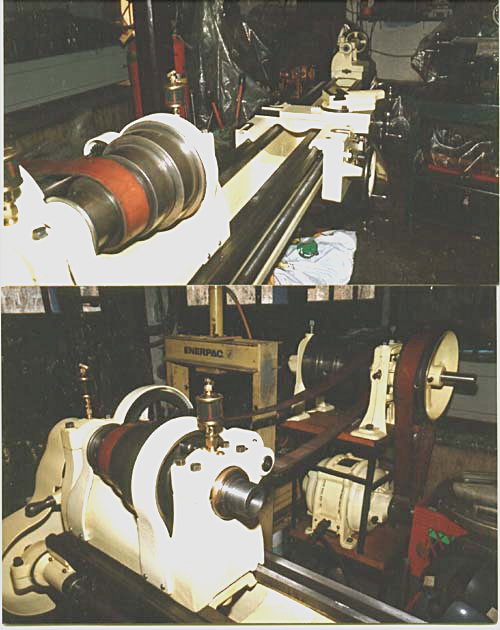

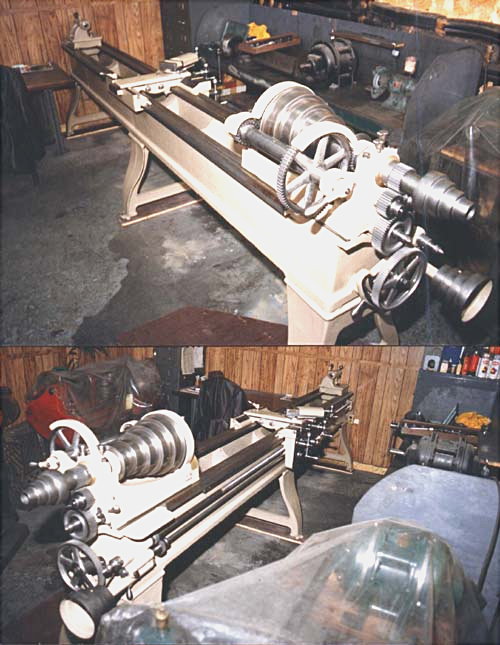

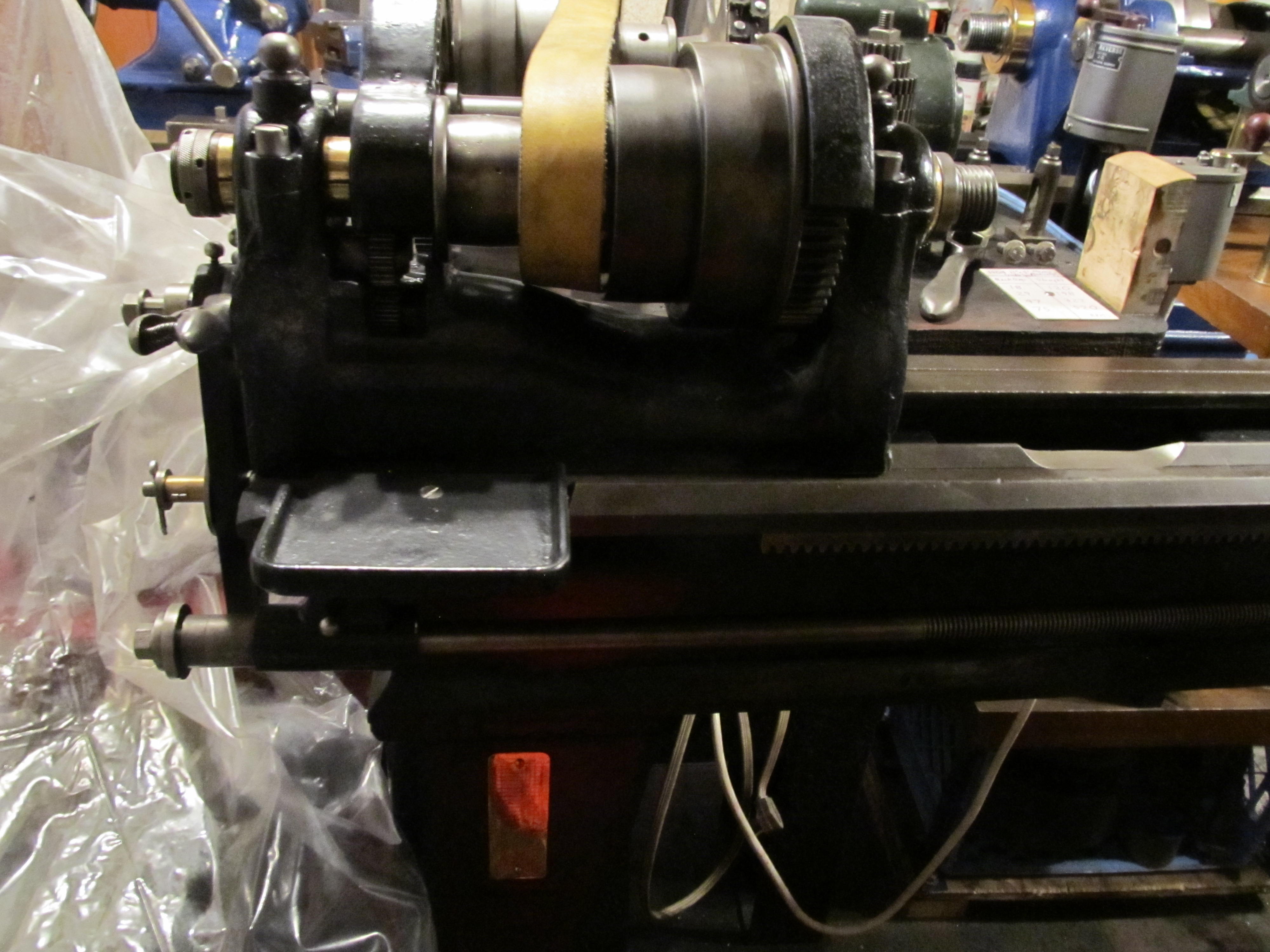

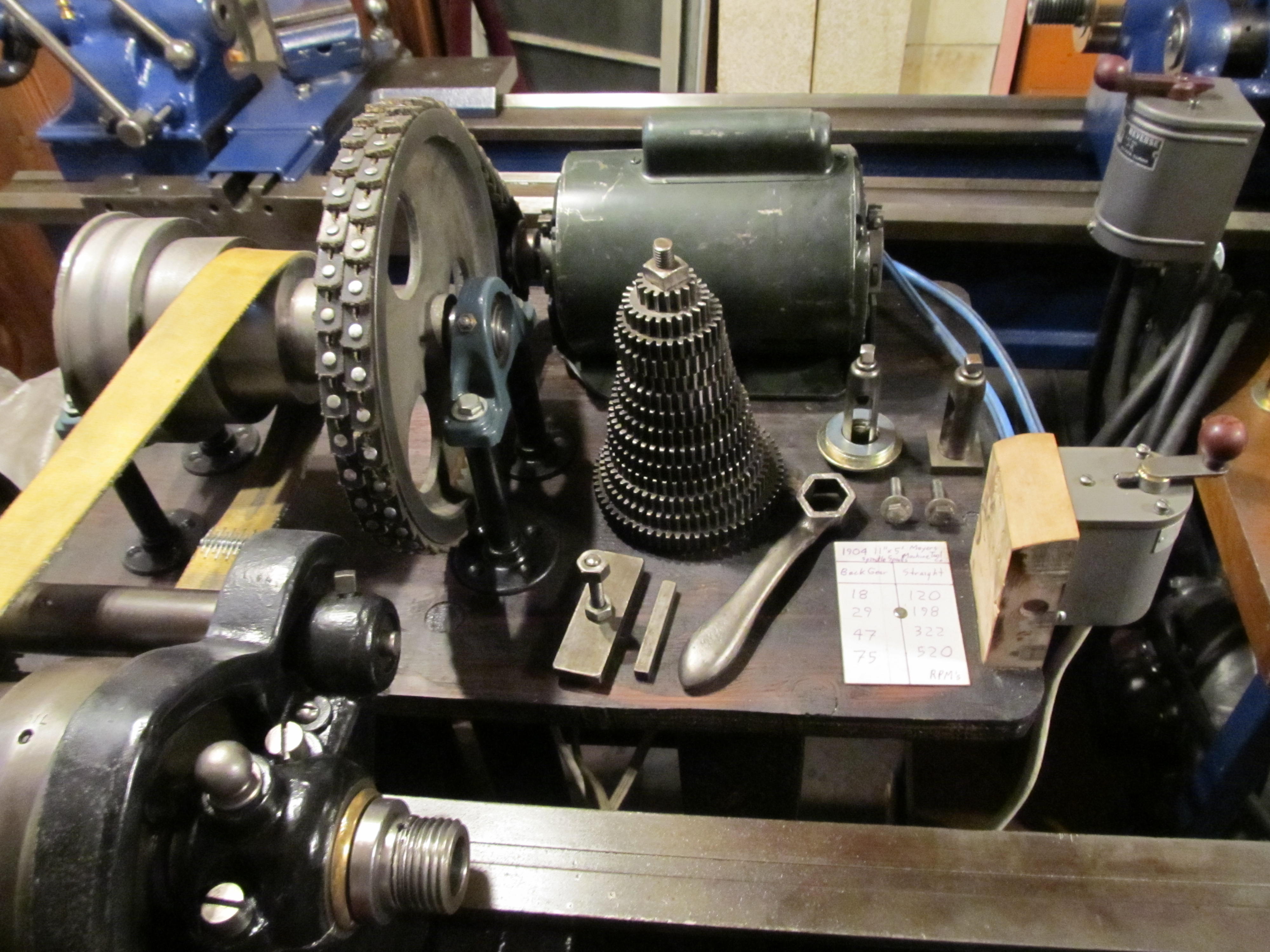

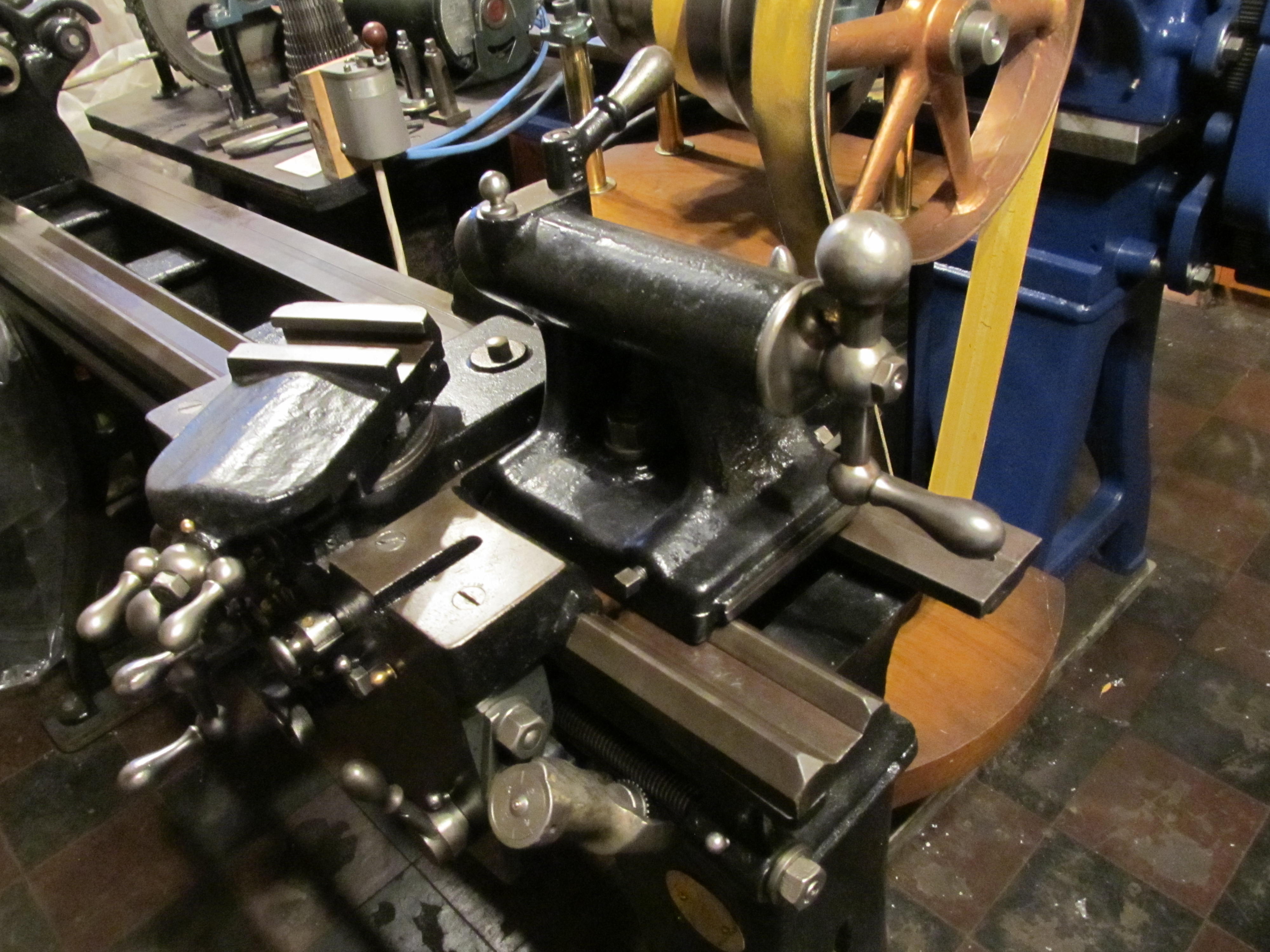

South Bend Lathe 18″x6″ 1911: A very early South Bend Lathe. Totally worn out, stored outside, badly repaired and horrible driveall attached. What haven’t we done to this one! This lathe recently machined an 18″ O.D.x 9″ I.D.x 6.75″ long cast iron main bearing ring for a 4′ elliptical chuck we engineered in the studio. How’s that for a come back!!! South Bend Lathe 18″x10′ 1919: This larger unit is shown in 2 views. On the left is a view of the lathe, and on the right is a view of the 3 hp. drive assembly. This machine has babbit spindle bearings and drip oilers. We restore the old 3 phase induction motors of preferably 1150 and 850 RPM (they’re hard to beat and very simple). We have gone away from leather belting as it rots, absorbs oil and stretches.

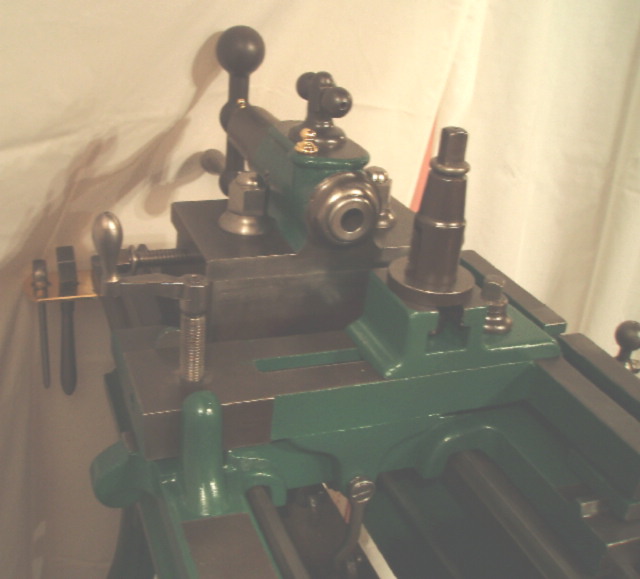

South Bend Lathe 18″x10′ 1919: This larger unit is shown in 2 views. On the left is a view of the lathe, and on the right is a view of the 3 hp. drive assembly. This machine has babbit spindle bearings and drip oilers. We restore the old 3 phase induction motors of preferably 1150 and 850 RPM (they’re hard to beat and very simple). We have gone away from leather belting as it rots, absorbs oil and stretches. Stark Mill 1920: Another bench top unit. The left view shows the front an drive setup. The right view shows the right side of the mill. There is very nice construction here rendering this a full blown pro machine tool as opposed to a hobbyist tool. We have cut many gears with this mill. It has a swiveling table making it a universal mill !!

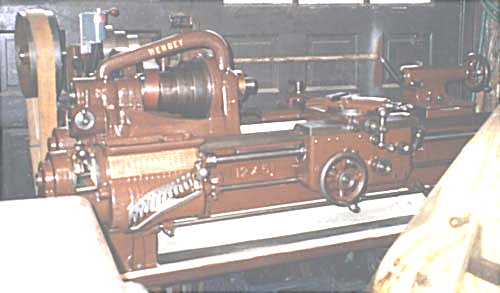

Stark Mill 1920: Another bench top unit. The left view shows the front an drive setup. The right view shows the right side of the mill. There is very nice construction here rendering this a full blown pro machine tool as opposed to a hobbyist tool. We have cut many gears with this mill. It has a swiveling table making it a universal mill !! Hendey Lathe 12″x5′ 1926: A great lathe, built many times stronger than it has to be! There are many advanced features on this machine. It restored beautifully and will easily hold .0001ths. Another earlier toolroom of the same size is currently being restored. This second lathe (1919) was missing the taper attachment, it was found with other parts (from 1912) on the internet!

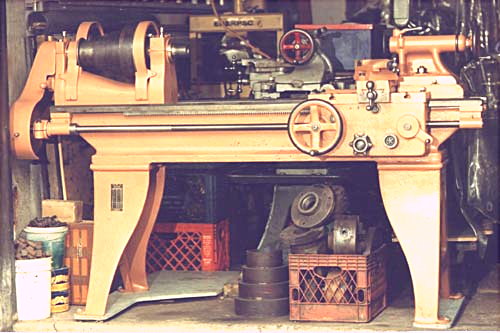

Hendey Lathe 12″x5′ 1926: A great lathe, built many times stronger than it has to be! There are many advanced features on this machine. It restored beautifully and will easily hold .0001ths. Another earlier toolroom of the same size is currently being restored. This second lathe (1919) was missing the taper attachment, it was found with other parts (from 1912) on the internet! Leblond Lathe 16″x12′ 1896 – 1906: Quite possibly the earliest Leblond lathe (by serial number) in existence! Very well made for the era. A great shafting lathe as it is built heavy as well. This lathe had a driveall bolted to it that twisted the long bed 3/4″! Upon removing it things went back to true. Since the photo the machine is under power and is a joy to use and watch.

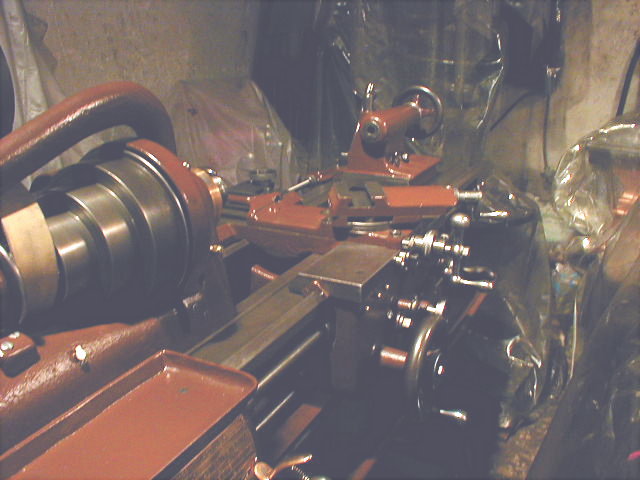

Leblond Lathe 16″x12′ 1896 – 1906: Quite possibly the earliest Leblond lathe (by serial number) in existence! Very well made for the era. A great shafting lathe as it is built heavy as well. This lathe had a driveall bolted to it that twisted the long bed 3/4″! Upon removing it things went back to true. Since the photo the machine is under power and is a joy to use and watch. Hendey Lathe 12″x5″ 1916/1919: This toolroom lathe was made from two machines. The legs, pan, bed, gearbox and side gearing came from a 1919 machine. The stub legs, headstock, tailstock, apron, saddle, compound and taper attachment were from a 1916 machine. Fitting had to be done and as well as indicating it. Note the horizontal drive unit. The results are very pleasing!

Hendey Lathe 12″x5″ 1916/1919: This toolroom lathe was made from two machines. The legs, pan, bed, gearbox and side gearing came from a 1919 machine. The stub legs, headstock, tailstock, apron, saddle, compound and taper attachment were from a 1916 machine. Fitting had to be done and as well as indicating it. Note the horizontal drive unit. The results are very pleasing!

This is a 1912 Rockford Milling Machine Co. vertical/horizontal milling machine. It is serial # 187. In 1908 the Dallin Bros. first marketed this machine without the over arm, vertical attachment and in a more basic from. They were reorganized into the National Machine Tool Works in 1909. In 1910 they were in turn reorganized into the Rockford Milling Machine Tool Co. Later they became the Sundstrand Corp. of hydraulic equipment.

This is a 1912 Rockford Milling Machine Co. vertical/horizontal milling machine. It is serial # 187. In 1908 the Dallin Bros. first marketed this machine without the over arm, vertical attachment and in a more basic from. They were reorganized into the National Machine Tool Works in 1909. In 1910 they were in turn reorganized into the Rockford Milling Machine Tool Co. Later they became the Sundstrand Corp. of hydraulic equipment.

This is a restored Meyers Machine Tool Co. 11″ x 5′ lathe that the machine dates to ca. 1905. To support that, we have found many companies that were not incorporated but were producing machines (in this case rural Columbia PA. at that time). As well, the fasteners are CRUDE. The bolts are all single point turned in a lathe (none from screw machines) and the nuts are very rough black smith made and tap threaded. Lots of hand finishing on parts all over the machine (not high grade at all). This four step cone pulley pattern of theirs is a heavier style and less refined (it one call call it that) than the later three step cone pulley style Meyers made. We decided to use a low R.P.M. 110v fractional motor on this lathe as it is a VERY light pattern for it’s size. Based on the experiences we have had restoring and using this lathe, we feel that it was a locally made lathe for rural farm and blacksmith application.

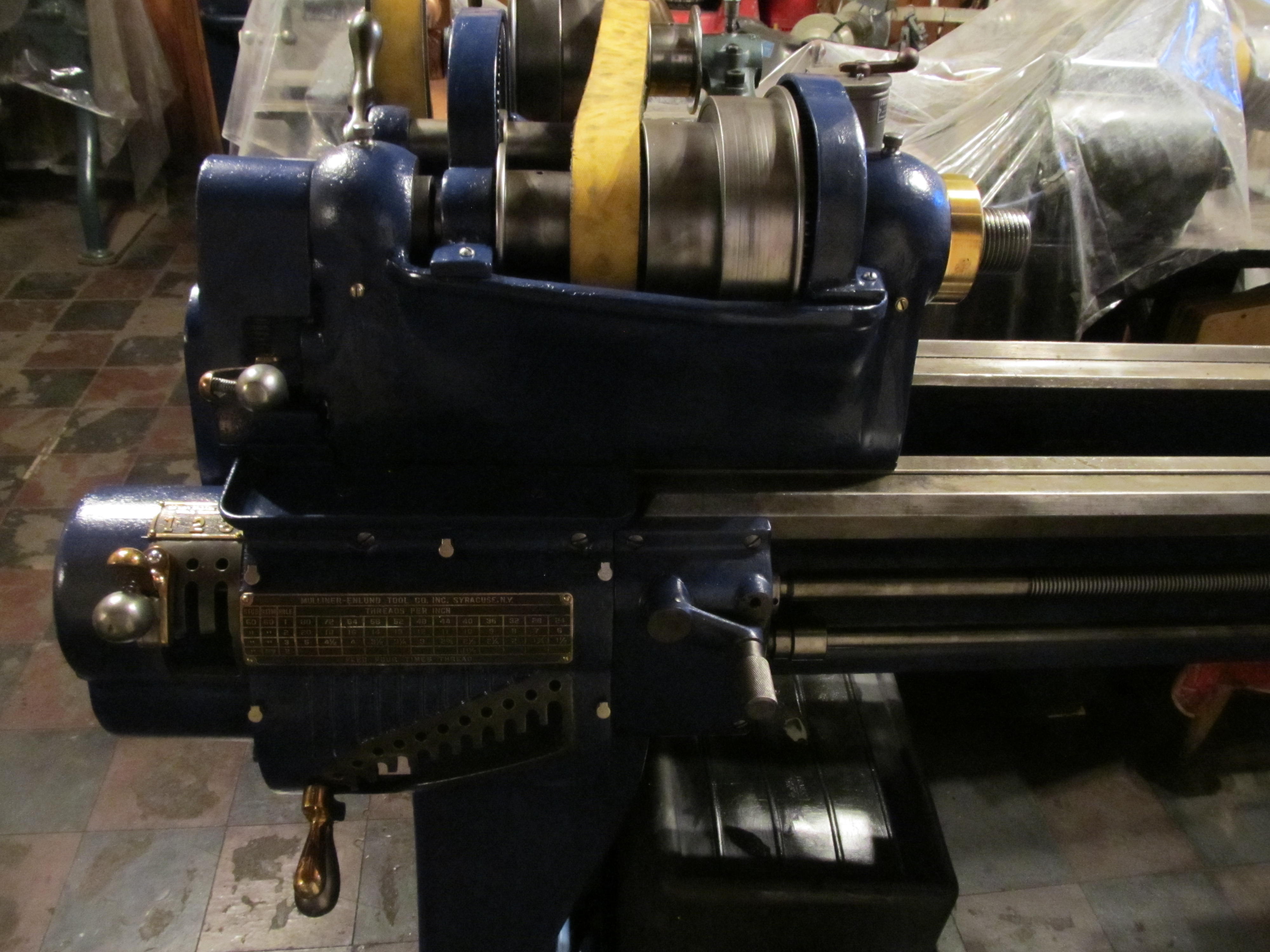

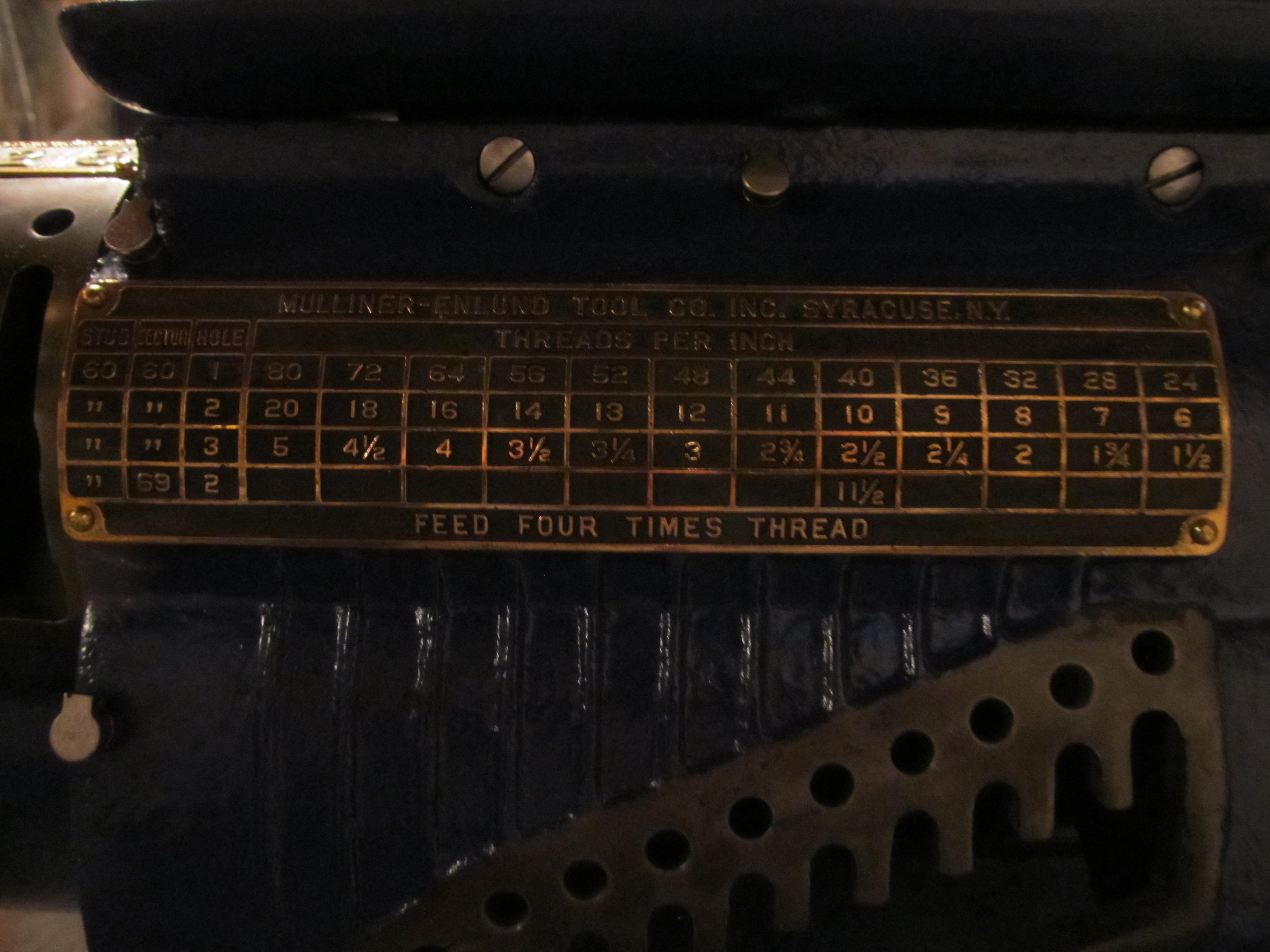

This is a Mulliner -Enlund 14″ x 6′ engine lathe. We restored and completely tooled it (follow, steady rests, head tail carriage tooling). The first image shows it in as found condition before rescue in the woods of Pennsylvania under a shed overhang. We estimate it’s outdoor “lawn furniture service” at between 20 and 30 years. The lathe has a “B” prefix before the serial number. The lathe has some interesting features resulting in a belief the this was a “B” grade machine produced buy this company. It is a late production machine dating to 1924. The castings are NOT cast iron but semi-steel. Heavier and harder with a tough skin. EVERY casting without exception has heavy porosity. As well the head stock spindle has a bore form the back end to the nose out of center line buy 1/8″ (we found this out when tying to fit a draw bar for collets to it). Apparently this was a “clean up” to use up any left over castings and parts to manufacture the last lathes. Hence, not a tool room unit. The down fall of the super heavy head stock design was the bowl shape. That dedicated the lathe to over head drive works only. We use horizontal drive systems that we fabricate. Therefore we had to drill perforated a “window” in the rear bowl section to give access to the belt coming out horizontally to our drive unit. That took 2 weeks of labor with some sections of the window being close to 3″ thick. This machine appears to be built under a Hendey license. The pattern is of a Hendey 12″ but raised in the castings to 14″. Some parts interchange some not. The apron uses cone clutches on straight gearing, not Hendey’s double and triple start worm wheels. The carriage feed trip rod operates only towards the headstock. A solid very powerful lathe.

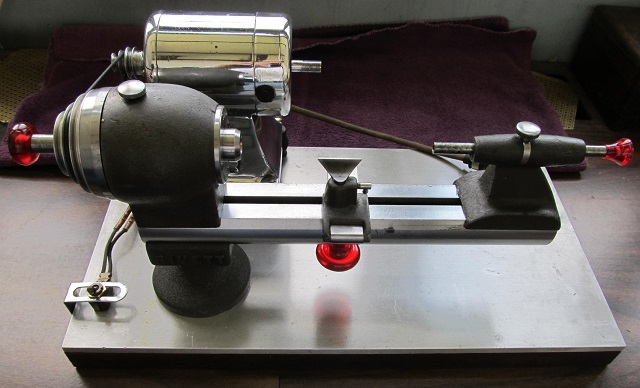

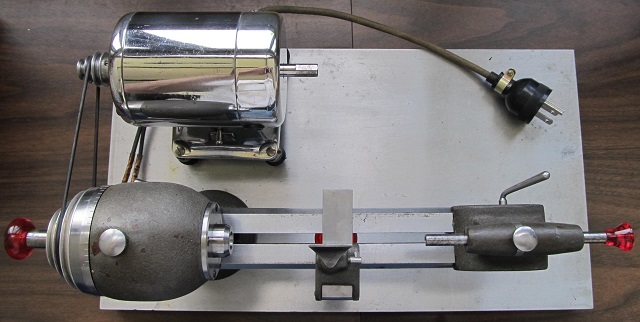

Here is a Rivett R-1 lathe. One of about 500 made between 1946 -50. These lathe were made post WWII to entice returning troops into the watchmaking trade. They were made in the Modernist “Buck Rodgers” style. This one needed the red Lucite knob for the collet draw bar. We made that out of the end of the handle of a well used Millers Falls screw driver of the same vintage.

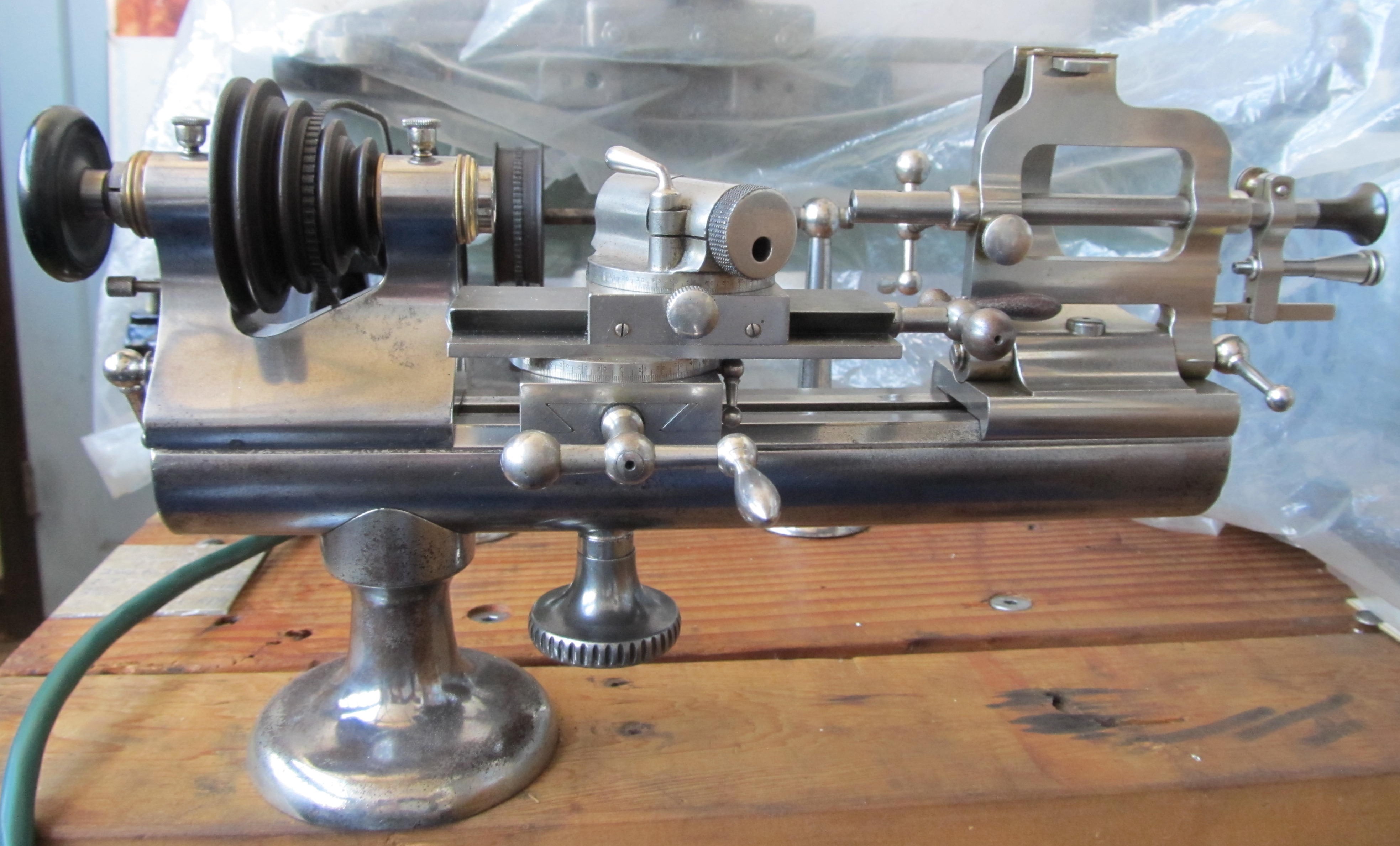

This next watchmakers lathe is a very early Rivett type 1a ca. 1887-90. We were able to locate a period correct compound and jeweling tailstock for it. It has been converted from 7.6mm to 8mm collets. Rivett lathes always were of stellar quality.

Slightly later is this Rivett type 1b ca. 1890-95. It came to us brush painted blue and rusted! In the face of neglect and abuse, these lathes survived. It has been converted from 7.6mm to 8mm collets.

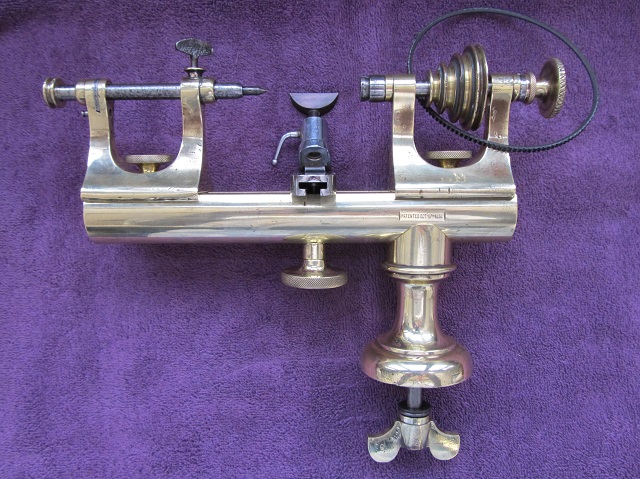

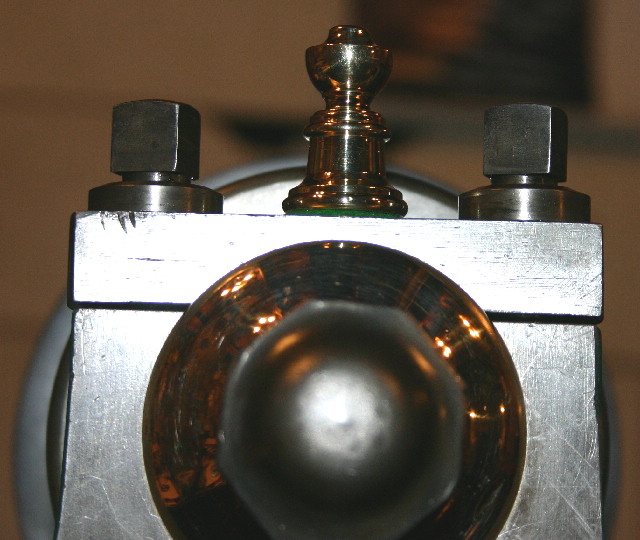

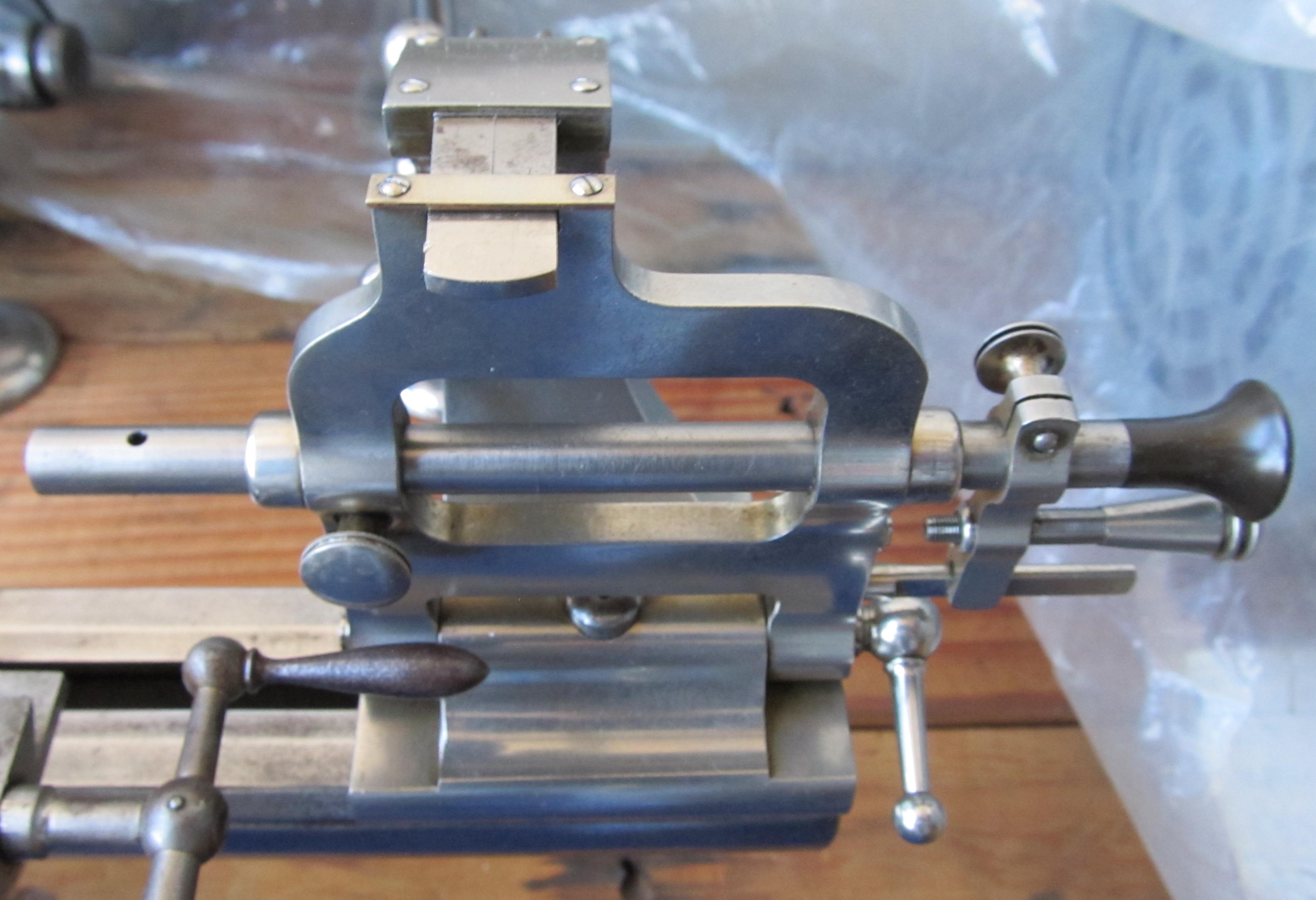

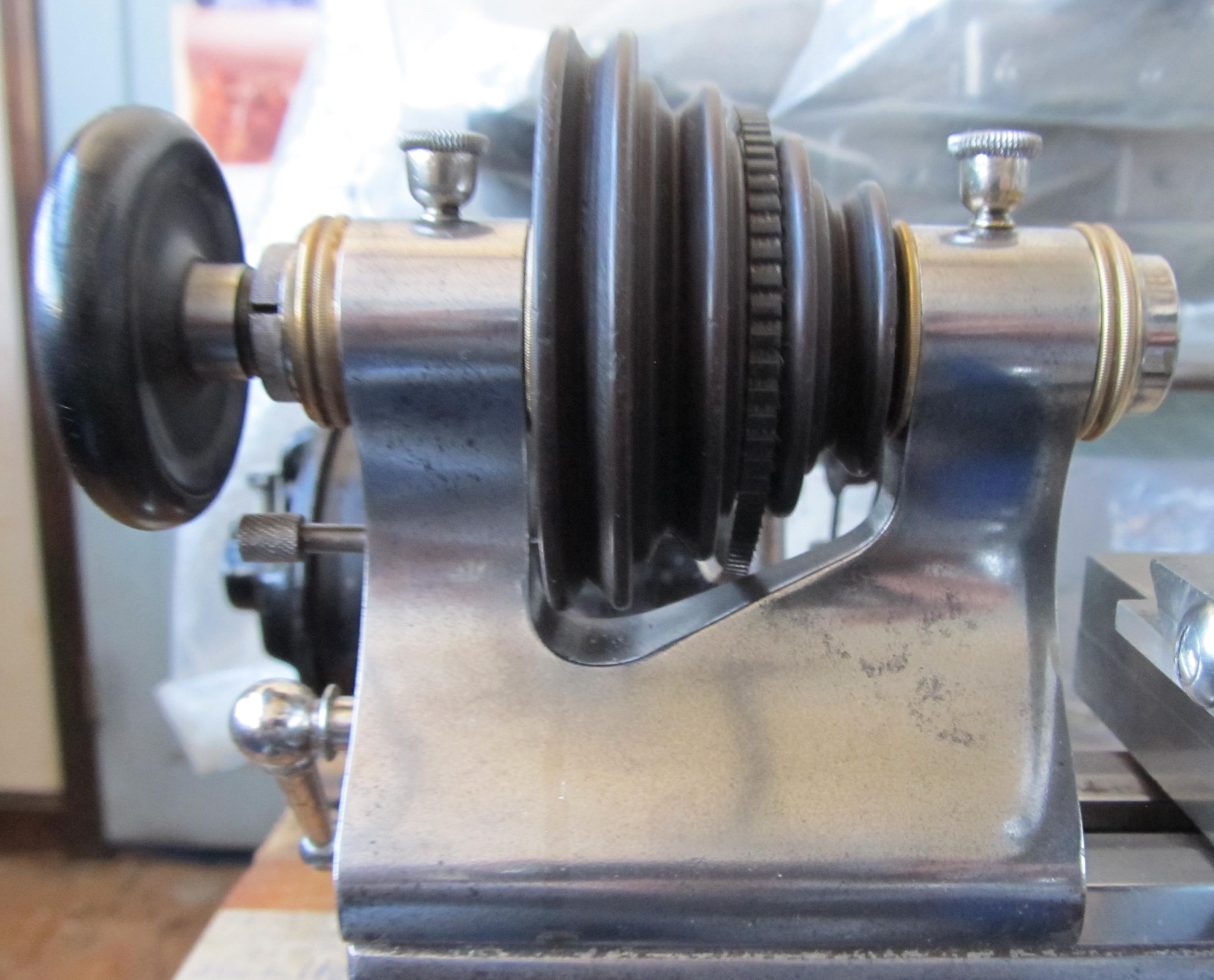

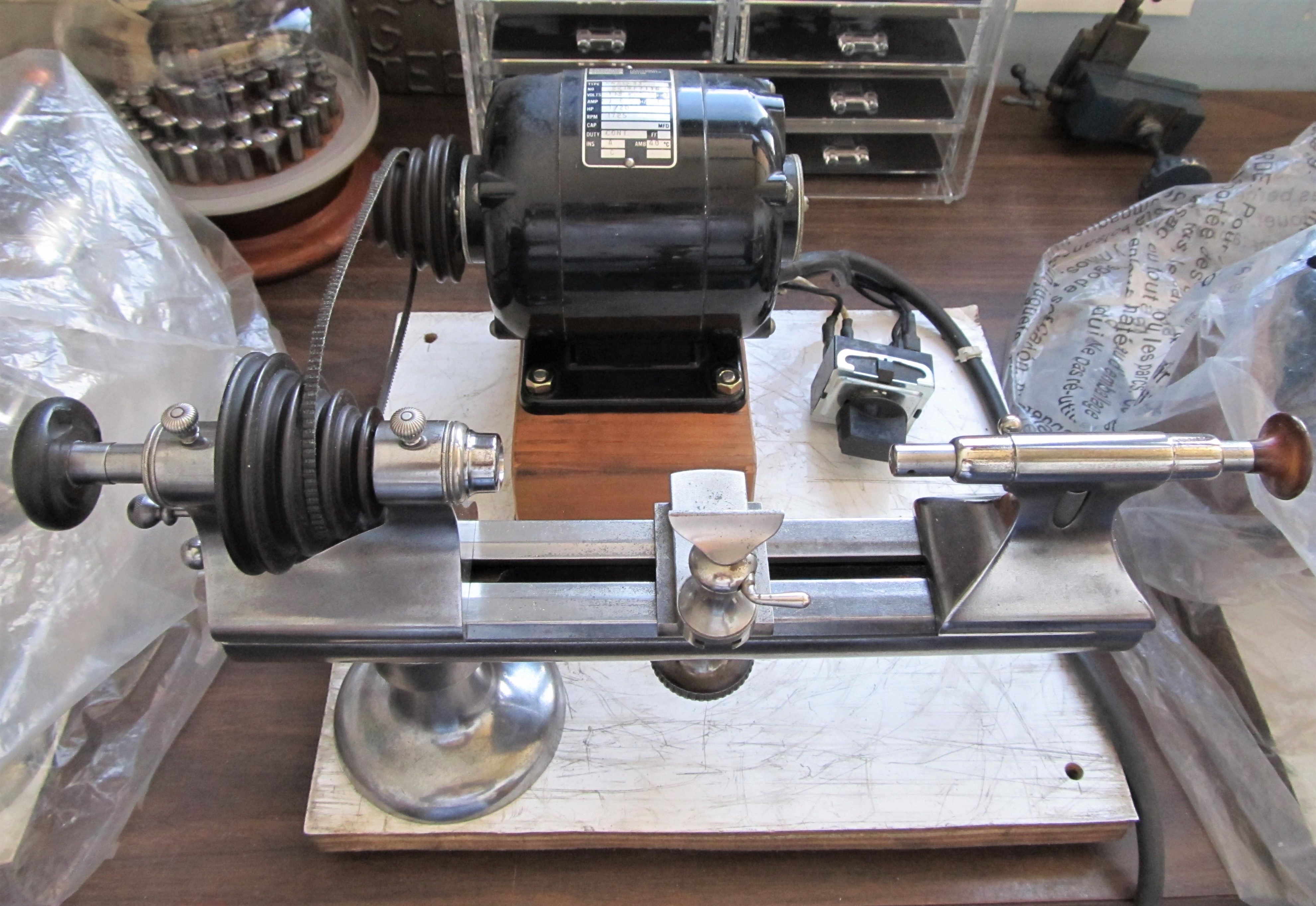

Stark made watch makers lathes at a very early date. We have what is apparently the oldest Stark lathe in existence ca. 1862. It is serial # 5. There is an Oct. 15, 1858 patent date alluding to the split collet design. It came with one original 5.5mm collet. The lathe is made of cast brass with lots of hand finishing on the mating surfaces of the headstock, tailstock and pedestal. It came to us completely tarnished and rusted.